If you work in telecommunications or networking, you may have heard of PLC splitters, but do you really know what they are and how they work? In this article, we will provide an introduction to PLC splitters, their functions, types, and applications.

What are PLC Splitters?

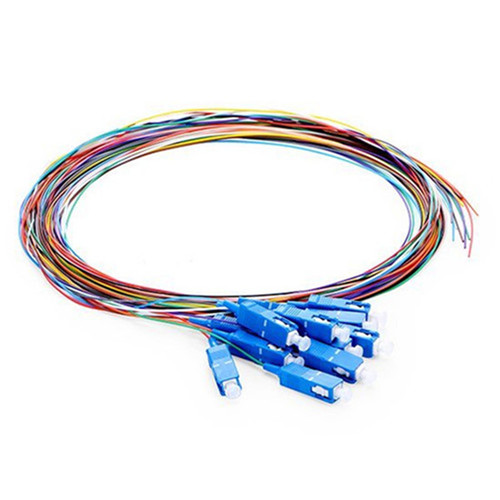

PLC splitters, or Planar Lightwave Circuit splitters, are passive optical components used to divide or split a single optical signal into multiple output signals. They are used in fiber-optic networks to distribute data or voice signals over long distances. PLC splitters can split a single input signal into multiple outputs with equal or unequal power, depending on the configuration.

PLC splitters are designed with a silica-based planar lightwave circuit, which is a chip with waveguides that split the optical signal. The waveguides are carefully designed and fabricated on the chip using lithography techniques. The chip is then coated with a protective layer and placed in a metal or plastic housing for protection.

Functions of PLC Splitters

PLC splitters have two main functions: splitting and combining signals. They can be used to split a single input signal into multiple output signals, or to combine multiple input signals into a single output signal. The output signals can have equal or unequal power, depending on the design of the splitter.

Types of PLC Splitters

PLC splitters are available in a variety of configurations, depending on the number of inputs and outputs, and the splitting ratio. The most common types of PLC splitters are:

- 1×2 splitter: This type of splitter has one input and two outputs. It is commonly used in fiber-optic networks to split a single signal into two signals.

- 1×4 splitter: This type of splitter has one input and four outputs. It is used to split a single signal into four signals.

- 1×8 splitter: This type of splitter has one input and eight outputs. It is used to split a single signal into eight signals.

- 1×16 splitter: This type of splitter has one input and sixteen outputs. It is used to split a single signal into sixteen signals.

- 1×32 splitter: This type of splitter has one input and thirty-two outputs. It is used to split a single signal into thirty-two signals.

- 2×2 splitter: This type of splitter has two inputs and two outputs. It is used to combine two signals into a single signal or split a single signal into two signals.

- 2×4 splitter: This type of splitter has two inputs and four outputs. It is used to combine two signals into a single signal or split a single signal into four signals.

Applications of PLC Splitters

PLC splitters have many applications in telecommunications and networking, including:

- Fiber-to-the-home (FTTH) networks: PLC splitters are used in FTTH networks to split a single optical signal into multiple signals, which are then distributed to individual homes or businesses.

- Cable television (CATV) networks: PLC splitters are used in CATV networks to distribute television signals to multiple homes or businesses.

- Local area networks (LANs): PLC splitters can be used in LANs to split or combine optical signals between network devices.

- Telecommunication networks: PLC splitters are used in telecommunication networks to split or combine optical signals between network devices, such as switches and routers.

- Data centers: PLC splitters are used in data centers to split or combine optical signals between servers and other network devices.

Advantages of PLC Splitters

PLC splitters offer several advantages over other types of splitters, including:

- Low insertion loss: PLC splitters have low insertion loss, which means that they do not degrade the signal as it passes through the splitter. This makes them ideal for use in high-bandwidth networks where signal loss is a concern.

- High reliability: PLC splitters are highly reliable, with a mean time between failures (MTBF) of over 50,000 hours. This means that they require less maintenance and are less likely to fail than other types of splitters.

- Wide operating temperature range: PLC splitters can operate over a wide temperature range, from -40°C to +85°C. This makes them suitable for use in harsh environments, such as outdoor installations or data centers.

- Compact size: PLC splitters are compact and lightweight, which makes them easy to install and transport. They can be mounted in small spaces or placed in a rack with other networking equipment.

Disadvantages of PLC Splitters

PLC splitters also have some disadvantages, including:

- Limited bandwidth: PLC splitters are limited in bandwidth, which means that they may not be suitable for high-speed networks that require high bandwidth.

- Limited customization: PLC splitters are typically designed for specific configurations, which means that they may not be customizable to meet specific requirements.

- Higher cost: PLC splitters are typically more expensive than other types of splitters, such as fused biconic taper (FBT) splitters. However, they offer higher performance and reliability, which may justify the higher cost.

Conclusion

PLC splitters are an essential component in fiber-optic networks, used to split or combine optical signals for distribution. They offer high performance, reliability, and a wide range of applications. When choosing a PLC splitter, it is important to consider the configuration, splitting ratio, and operating temperature range to ensure compatibility with the network.