Fiber distribution boxes (FDBs) are an essential component of fiber optic networks, providing a centralized point for distributing and managing fiber optic cables. FDBs offer a secure and organized way to terminate, splice, and connect fiber optic cables, as well as protecting them from external damage.

In this post, we’ll discuss what fiber distribution boxes are, their features, benefits, and how they work.

What is a Fiber Distribution Box?

A fiber distribution box is a device used to terminate, connect, and splice fiber optic cables. It is a critical component in fiber optic networks, where it provides a centralized point for managing cables and ensuring network reliability. FDBs come in various sizes, designs, and capacities, depending on the specific application and network requirements.

Features of Fiber Distribution Boxes

Fiber distribution boxes have several features that make them ideal for managing fiber optic networks. Here are some of the key features:

- Durability: Fiber distribution boxes are designed to withstand harsh environmental conditions such as extreme temperatures, moisture, and physical impacts.

- Flexibility: FDBs can accommodate different types of fiber optic connectors and splices, making them versatile for various network applications.

- High-density: FDBs can support a high concentration of fiber optic cables and connections, providing a centralized point for managing large fiber optic networks.

- Easy installation and maintenance: FDBs are designed for easy installation and maintenance, allowing technicians to access and service the equipment quickly.

Benefits of Fiber Distribution Boxes

Fiber distribution boxes offer several benefits for fiber optic networks, including:

- Improved network reliability: FDBs provide a secure and organized way to manage fiber optic cables, protecting them from external damage and minimizing the risk of network downtime.

- Reduced installation time and cost: FDBs are designed for easy installation, which can help reduce installation time and cost.

- Scalability: FDBs can accommodate the expansion of fiber optic networks by providing additional capacity for terminating and splicing fiber optic cables.

- Versatility: FDBs can support various fiber optic connectors and splices, making them versatile for different network applications.

How Fiber Distribution Boxes Work

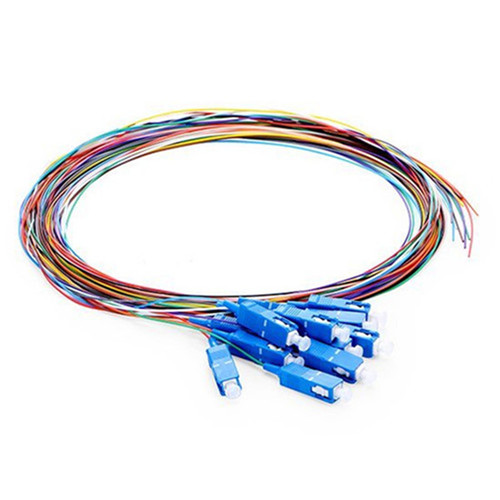

Fiber distribution boxes work by providing a centralized point for managing fiber optic cables. They typically have multiple ports and can support various types of connectors and splices. The incoming fiber optic cables are terminated, spliced, or connected to fiber optic pigtails, which are then connected to the ports on the FDB.

Fiber distribution boxes can also have built-in splitter modules that split the incoming signal into multiple outputs, allowing the network to serve multiple users or locations. They may also have additional features such as cable management, strain relief, and grounding.

Conclusion

Fiber distribution boxes are critical components of fiber optic networks, providing a centralized point for managing and distributing fiber optic cables. They offer several benefits, including improved network reliability, scalability, and versatility. When choosing an FDB, it’s essential to consider the specific network requirements, the number of ports and connectors needed, and the overall capacity.

With the right fiber distribution box, fiber optic networks can operate reliably, efficiently, and securely.

Bativ Sayings to Fiber Distribution Box Buyers

- Advantages of using fiber distribution boxes for network management

- Improved organization and protection of fiber optic cables

- Reduced risk of cable damage or breakage

- Increased reliability and efficiency of network performance

- Different types of fiber distribution boxes and their applications

- Wall-mount vs. rack-mount fiber distribution boxes

- Indoor vs. outdoor fiber distribution boxes

- Distribution vs. termination fiber distribution boxes

- Components of a fiber distribution box

- Splice trays

- Adapters

- Pigtails

- Patch cords

- Cable management accessories

- Factors to consider when selecting a fiber distribution box

- Capacity and port density

- Material and durability

- Compatibility with existing network components

- Environmental factors (e.g. temperature, humidity, exposure to sunlight)

- Steps for installing and configuring a fiber distribution box

- Site preparation and equipment/tools needed

- Cable routing and termination

- Splice tray placement and organization

- Adaptor and pigtail installation

- Testing and troubleshooting

- Common issues and troubleshooting tips for fiber distribution boxes

- Loose or damaged fiber connections

- Cable routing or management problems

- Dust or debris accumulation

- Environmental damage (e.g. exposure to water, extreme temperatures)

- Best practices for maintaining and cleaning fiber distribution boxes

- Regular inspection and cleaning of fiber connections

- Replacement of damaged or worn components

- Monitoring of environmental factors and addressing issues as needed

- Keeping accurate records of maintenance and repairs

- Future trends in fiber distribution box technology

- Integration with smart network management tools

- Increasing use of cloud-based management systems

- Development of more compact and customizable fiber distribution boxes

These additional topics can provide readers with a more comprehensive understanding of fiber distribution boxes and their applications, as well as tips for selecting, installing, and maintaining them effectively.